lides are a popular playground feature, offering children endless hours of fun. When purchasing slides, considering factory direct sales can be advantageous. Here’s a comprehensive look at slide functionality, factory advantages, materials used, and the manufacturing process.

Slides are designed to provide a thrilling and enjoyable experience for children.

They come in various shapes and sizes, including straight, spiral, and wave designs. The primary functions of a slide include:

· Encouraging Physical Activity: Slides promote physical exercise and help develop gross motor skills as children climb and slide down.

· Enhancing Social Interaction: Slides are often a focal point in playgrounds, encouraging children to interact and play together.

· Boosting Confidence: Sliding down a slide can help children overcome fears and build confidence in their abilities.

· Cost Efficiency: Factory direct sales typically eliminate the middleman, resulting in lower prices for consumers.

· Customization Options: Direct purchasing often allows for greater customization, enabling buyers to choose specific designs, colors, and features.

· Quality Assurance: Buying straight from the factory can ensure that the slides meet industry standards and quality controls.

· Faster Delivery: Manufacturers can provide quicker turnaround times compared to third-party retailers.

The process of manufacturing a slide involves several key steps:

1. Design and Planning: The initial stage involves designing the slide with safety, functionality, and aesthetics in mind. CAD software is often used to create detailed plans.

2. Material Selection: Based on the design, the appropriate materials are selected for durability, safety, and cost-effectiveness.

3. Fabrication: Materials are cut, shaped, and assembled. For plastic slides, this often involves rotational molding or blow molding. Metal slides are usually fabricated through welding and finishing processes.

4. Quality Control: The slide undergoes rigorous testing to ensure it meets safety standards and durability requirements.

5. Finishing Touches: This includes painting, coating, or adding any additional features like handrails or splash guards.

6. Inspection and Packaging: Final inspections are conducted to ensure the slide is defect-free before it is packaged and shipped.

Slides offer not only joy and excitement but also valuable developmental benefits. Investing in high-quality slides creates a fun and enriching play environment, fostering growth and happiness for children. Embrace the ultimate playground experience with slides that deliver both entertainment and educational value.

|

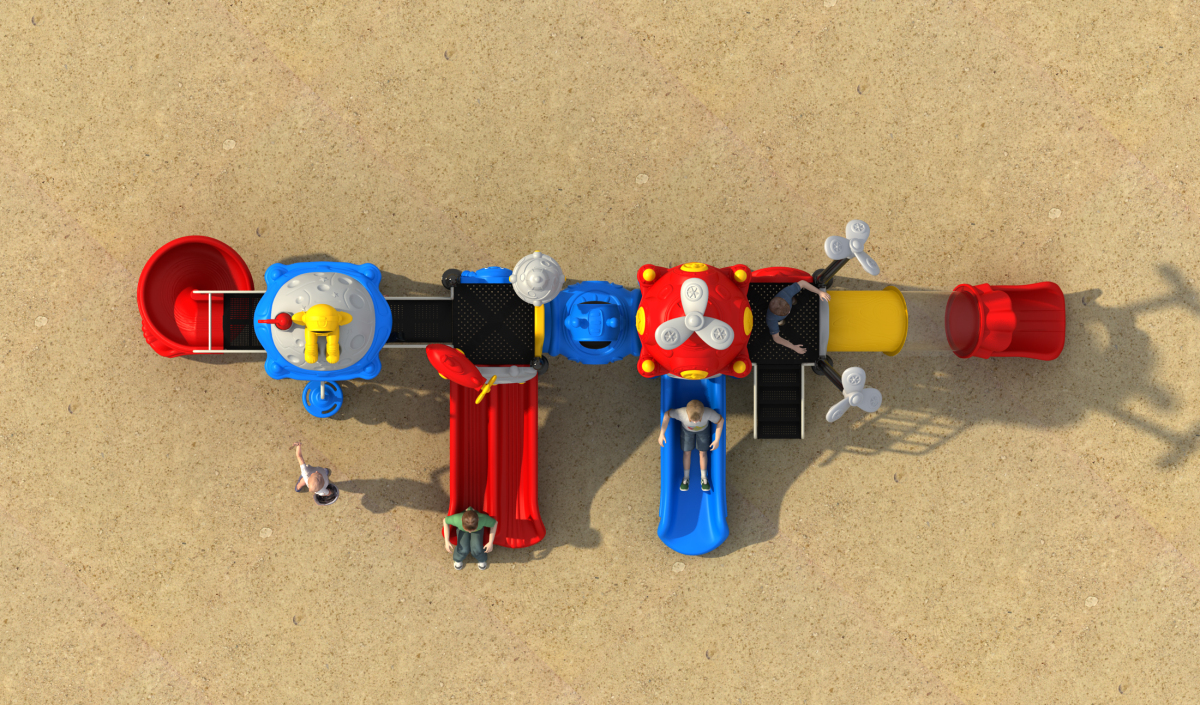

Product Size: |

880*270*380cm |

|

Color: |

Customized Color |

|

Player age: |

3-15years |

|

MOQ: |

1 set / 20GP container /40HQ container |

|

Advantage: |

1. Anti-UV b. Anti-static 2. Security 3. Environmental protection 4. Color is not easy to fade |

|

Material: |

1. Plastic parts: LLDPE, Roto-moulded

2. Metal parts: Galvanized steel pipe, color powder coated

3. Platform/Stepped-ladder: Steel sheet, color powder coated or PVC coated

Advantage of PVC coated: 1) PVC coated is soft and thus prevents kids from bruising. 2) Extreme weather, PVC coating prevent the deck and stepped-ladder getting too hot or cold |

|

Occasion: |

amusement park, shopping mall, Pre-school,kids hospital, airport, outdoor public playground,camping area, city park , kindergarten, kindergarten, training center |

|

Remarks: |

1.Please check the screws and other catchers regularly to assure the firm structure. 2.Please make sure that all the kids play with adult supervision. 3.Blunt objects and acid corrosive liquor are forbidden |

Name: sunny

Mobile:86-13958925282

Tel:86-13958925282

Whatsapp:86-13958925282

Email: info@qirenplay.com

Add:Xi’Ao Industrial Zone,Qiaoxia Town,Yongjia County,Wenzhou city,zhejiang province ,China